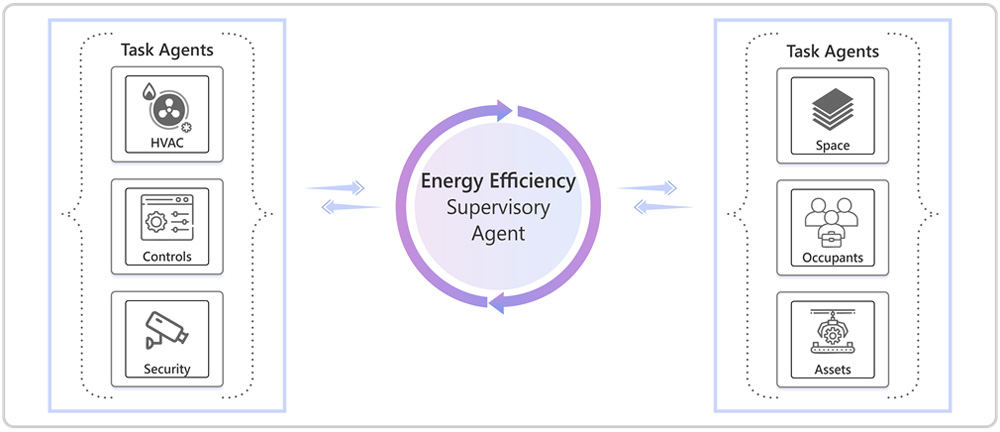

Handle specific optimization tasks within their area of expertise, working under the guidance of the supervisor agent. Examples include:

- Space Optimization Agent: Maximizes the use of available space to reduce energy costs and enhance comfort.

- Layout Recommendation Agent: Suggests floor plan adjustments to streamline workflows and minimize unnecessary energy use.

- Asset and Inventory Management Agent: Tracks equipment usage and inventory levels to avoid energy waste and ensure efficient operations.

- Predictive Maintenance Agent: Monitors equipment health, predicts failures, and schedules maintenance to prevent downtime and unnecessary energy consumption.